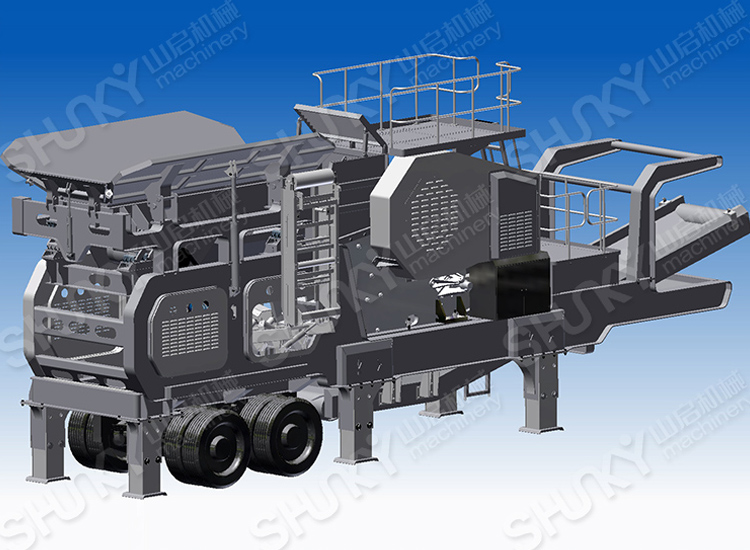

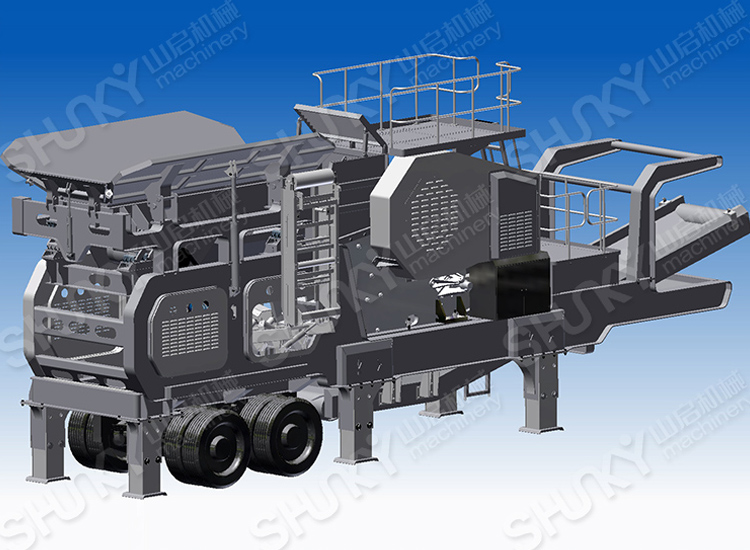

Mobile crushing station is mainly used to process materials in metallurgy, chemical industry, building construction, hydropower project, etc. which needs to be moved around frequently. It is especially applied in the crushing and screening work of movable materials in highway, railway and hydropower engineering project. Users can adopt a variety of configuration forms according to different kinds of raw material processed, scales, and final products. In recent years, it has made outstanding contributions in the construction wastes recycling engineering.

Integrated mobile station reduces the difficulties in building infrastructure for separated components and installing auxiliary facilities. It can save a lot of infrastructure and relocation cost. Besides, it also can conduct crushing work on site and move according to the sites of raw materials, which greatly reduce the transportation cost. The station truly provides customers with high efficient and low-cost hardware facilities for the operation of project.

◎ Features

1.dular design makes it flexible and can be combined with other machines freely. Wheel-mounted traction, compact structure and stability make mobile crushing station satisfy the demand of mobility no matter at the work site or on the road. Various models can quickly combine with other models to meet the different needs of production.

2.On-site working helps reduce transportation cost. The work is conducted by various equipments which can crush the materials on the site. The finished products can meet the needs of customers directly, which reduces the material transportation cost.

3.Strong adaptability and on-demand customization. This crushing station is equipped with independent generator. The machine can work normally even there is no local power. At the same time, we can customize mobile crushing plant according to customer's site, quality of materials and shape of products.

4.Compact structure and reliable performance. Mobile crushing station integrates the superior vibrating feeder, crushers, vibrating screen, vehicle motor and control box as a whole, which makes the station have compact structure and reliable running.

5.Reasonable bearing structure and fast installation. Mobile crushing station can be put into use just after simple processing of supporting parts. It is convenient to disassemble and transport without any residual loss if it need be moved to other places.

◎ Specification

| Item | Unit | ME46C24 | ME57C24 |

| Transportation Length | mm | 13700 | 14000 |

| Transportation Width | mm | 2800 | 2800 |

| Transportation Height | mm | 4500 | 4600 |

| Ma×imum Length | mm | 14500 | 14650 |

| Ma×imum Width | mm | 2800 | 2800 |

| Ma×imum Height | mm | 5830 | 5980 |

| Weight | t | 38 | 45 |

| Tire Configuration |

| Dual-a×ial | Dual-a×ial |

| Vibrating Feeder |

| GZD960×3800 | GZD960×3800 |

| Crusher |

| PE400×600 | PE500×750 |

| Discharging Belt Conveyor |

| B650 × 6.5M | B650 × 6.5M |

| Belt Conveyor above Vibrating Screen |

| B650 × 10.5M | B650 × 10.5M |

| Vibrating Screen |

| 3YZS1237 | 3YZS1237 |

Products

Products

Contact Us

Contact Us